Artificial Intelligence

Engineering

+ 3 more ...

Parexus: The AI-Driven Future of Engineering Inspections

12 Feb 2026

by Nadiy, Senior Content Writer

Contributor, Nurul, Senior Product Owner

12 Feb 2026

by Nadiy, Senior Content Writer

Contributor, Nurul, Senior Product Owner

Artificial Intelligence

Engineering

Industry 4.0

Software Development

PWA

Parexus: The AI-Driven Future of Engineering Inspections

Table of contents

Contact us

We will get back to you in the next 48 hours.

Manual inspections, scattered workflows, and slow reporting have long defined on-site engineering. Parexus is changing that narrative with AI-powered inspections and a smart digital platform built for real-world conditions. This client story explores how Sentry brings structure, speed, and clarity to Industry 4.0 operations.

key takeaways

Engineering sites are not short on data. What they lack is time. Time spent walking large facilities, manually inspecting assets, documenting issues, escalating findings, and waiting for approvals. For decades, this has been the reality of on-site engineering work, critical, complex, and heavily manual. Parexus set out to change that.

As a deep-tech startup operating at the intersection of AI and engineering, Parexus isn’t chasing innovation for innovation’s sake. They are solving a very real, very human problem: how to reduce manual inspection work on engineering sites while increasing accuracy, accountability, and speed.

This is where their Sentry platform, and their collaboration with Lizard Global, began.

Want to find out how much it costs to build your dream app or web app?

Meet Parexus: A Deep-Tech Startup with a Clear Mission

Parexus is a deep-tech startup focused on integrating AI into the engineering industry. Led by Jeremy Ong, the team recognized a critical gap in how inspections and maintenance processes are handled on-site.

In industries operating under Industry 4.0 standards, engineering inspections are still largely manual. Engineers on-site are required to visually inspect assets, capture findings, write reports, and escalate issues through multiple layers of review. The process is time-consuming, prone to inconsistency, and heavily dependent on individual experience.

Parexus envisioned a smarter way. Their idea was simple in concept, yet complex in execution: empower engineers on-site to take photos, submit them through a digital platform, and let AI analyze the images to determine whether maintenance is required. The result would be faster inspections, standardized reporting, and clearer decision-making.

What they needed was not just AI, but a platform capable of supporting the entire workflow around it.

The Real-World Challenge: Manual Inspections at Scale

On-site engineering inspections involve far more than just checking assets. There are campaigns to organize, teams to assign, inspection routes to plan, and multiple stakeholders to keep aligned.

Admin teams must define maintenance campaigns, operators must carry out inspections, and quality teams must validate results before work is approved or escalated.

Before Sentry, this process was fragmented. Engineers relied on manual documentation, disconnected tools, and repeated back-and-forth between roles. Inspections could take longer than necessary, and insights were often delayed by process bottlenecks rather than technical limitations.

Parexus needed a way to orchestrate this complexity, without slowing teams down.

The Sentry Solution: AI-Powered Inspections Backed by a Smart Platform

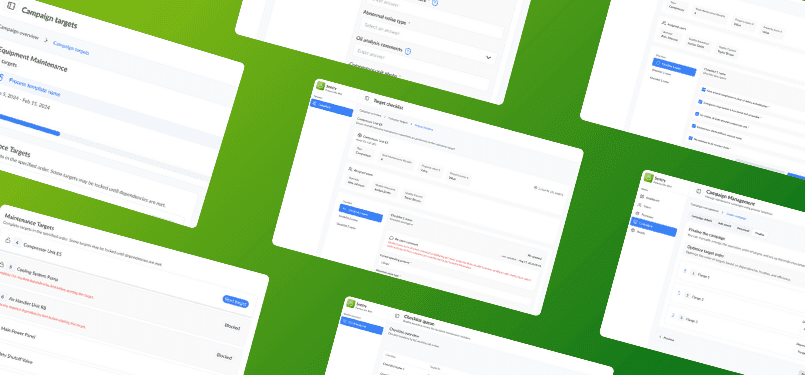

Sentry was designed as a responsive web application and Progressive Web App (PWA) that acts as the backbone of Parexus’ AI-powered inspection workflow.

At its core, the solution integrates Parexus’ proprietary image analysis AI into a structured, role-based platform that supports the entire maintenance lifecycle.

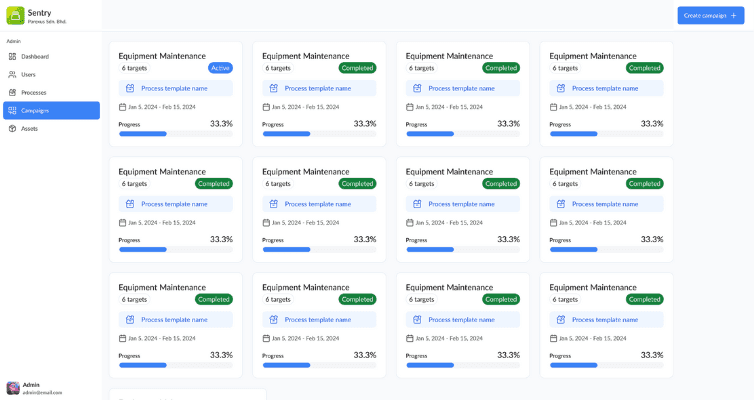

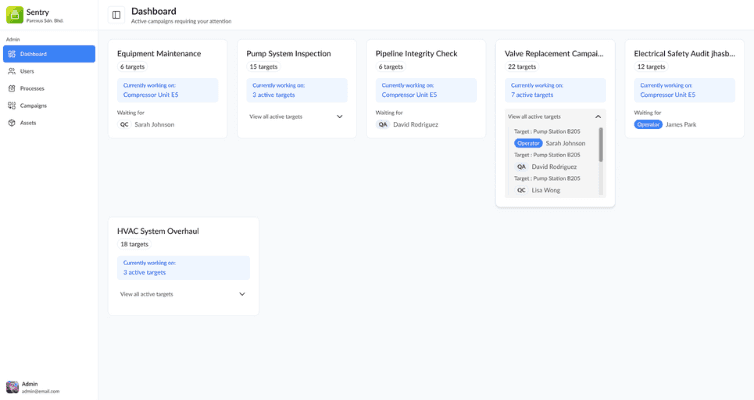

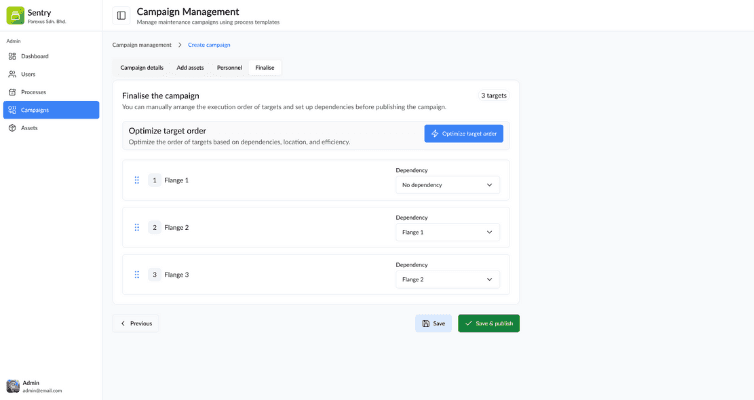

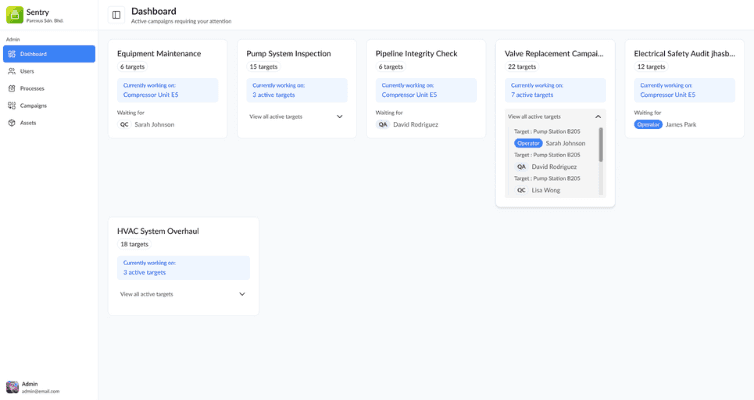

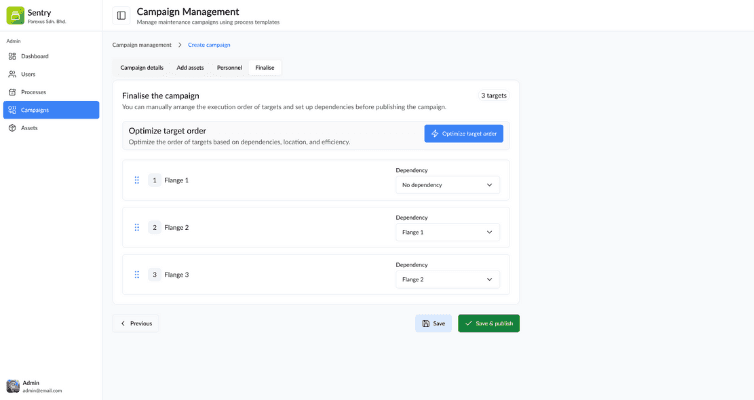

The process begins with the admin. Admins are responsible for setting up inspection campaigns. They define what needs to be inspected, assign team members, and map out routes for operators to follow on-site. Inspired by operational models used by industry leaders like Petronas, the system helps optimize inspection paths so engineers can move efficiently across large sites.

Once a campaign is live, operators, typically engineers on-site, receive their assigned inspections through the app. They follow the predefined route, capture images, and submit them directly within the platform. This is where Artificial Intelligence (AI) steps in. Between the operator and the quality control stage, Parexus’ image analysis AI evaluates the submitted photos. If no issues are detected, the process can move forward without delay. If potential problems are identified, the findings are flagged for further review.

A Structured Workflow Built for Engineering Reality

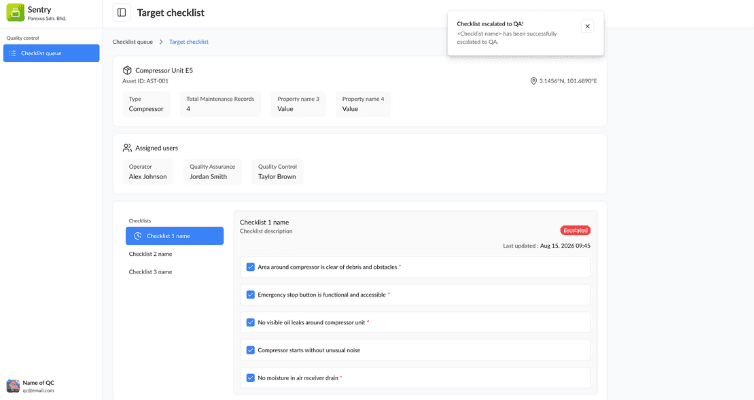

One of the defining strengths of the Sentry platform is how clearly it reflects real-world engineering workflows. The system supports four key roles, each with a distinct responsibility.

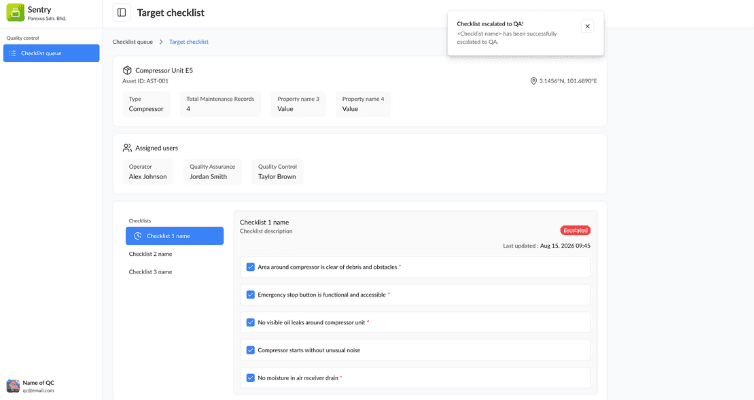

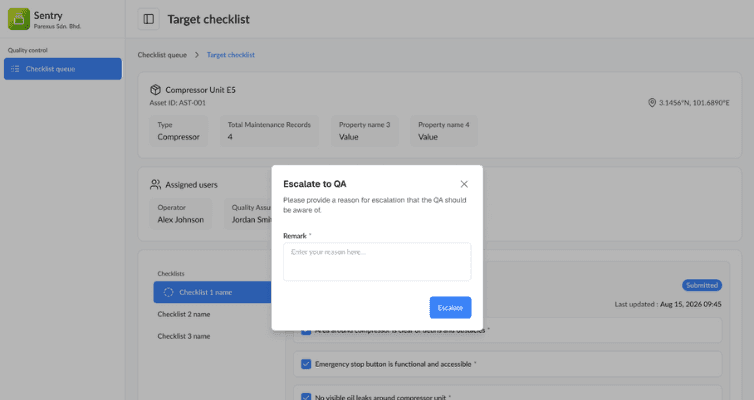

Admins handle campaign setup, route planning, and team assignments. Operators perform on-site inspections based on their assigned campaigns. The AI acts as an intelligent layer between inspection and validation, analyzing images and surfacing actionable insights. Quality Control (QC) managers review findings and approve next steps, while Quality Assurance (QA) managers handle escalations when issues require deeper investigation or rework.

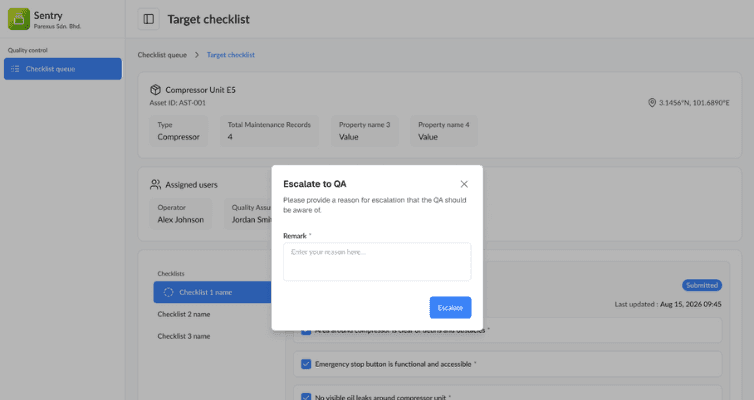

If problems arise, the workflow allows findings to be escalated from QC to QA, and, if necessary, back to the operator for reassessment. This creates a closed feedback loop that ensures issues are addressed, verified, and documented, without losing visibility along the way.

The result is a system that mirrors how engineering teams actually work, rather than forcing them to adapt to rigid software constraints.

Lizard Global’s Role: Turning AI Vision into a Scalable Platform

While Parexus brought deep domain expertise and proprietary AI technology to the table, they needed a digital partner to bring the platform itself to life.

Lizard Global supported Parexus across software development and UI/UX design, ensuring the platform was not only technically powerful, but also intuitive for engineers working in demanding on-site environments.

From a user experience perspective, the challenge was clear: the app had to be fast, responsive, and easy to use, even in less-than-ideal conditions. Operators needed to submit inspections quickly, admins needed clarity over campaign status, and quality teams needed confidence in the data they were reviewing. From a technical standpoint, the platform required seamless API integration with Parexus’ AI, a reliable feedback loop between roles, and the scalability to support growing inspection volumes across sites.

Together, these elements formed a cohesive system designed for real-world use, not just theoretical efficiency.

Key Features That Drive Impact

The Sentry platform brings together several critical features that support AI-powered inspections at scale. Engineers can submit inspection images directly through the app, reducing reliance on manual reporting. A built-in feedback loop ensures findings are reviewed, escalated, and resolved within a single system.

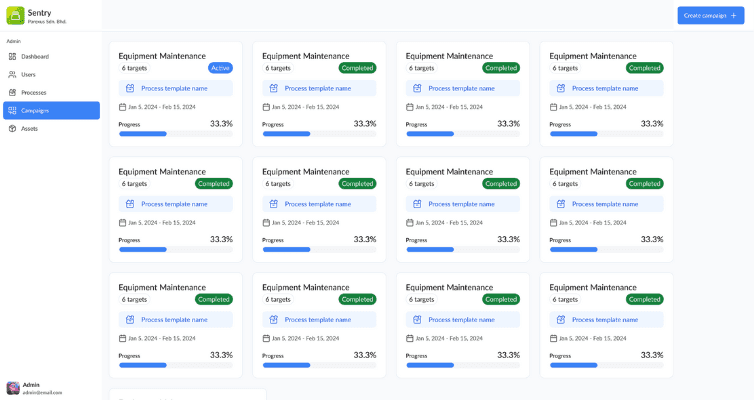

API integrationsallow the AI engine to analyze images in real time and return detailed reports. Campaign management tools give admins visibility and control over inspections, routes, and team assignments.

Because the solution is delivered as a responsive web app and PWA, teams can access it across devices without compromising performance or usability.

The Impact: Less Manual Work, Smarter Decisions

The impact of Sentry is felt where it matters most, on-site. By automating image analysis and streamlining inspection workflows, Parexus helps engineering teams significantly reduce manual effort. Inspections become faster, reporting becomes more consistent, and decision-making is supported by AI-driven insights rather than fragmented documentation.

Quality teams benefit from clearer visibility and structured escalation paths. Admins gain better oversight of campaigns and resources. Operators spend less time on paperwork and more time focusing on critical engineering work.

In short, automation doesn’t replace engineers, it empowers them.

Supporting Industry 4.0 Through Practical Innovation

Parexus’ work sits firmly within the principles of Industry 4.0: digitalization, automation, and intelligent systems that improve operational efficiency.

What makes their approach stand out is its practicality. Instead of forcing radical change, Sentry enhances existing processes with AI and thoughtful platform design. It respects the realities of engineering environments while introducing smarter, more scalable ways of working.

This balance between innovation and usability is what turns technology into real business impact.

How Lizard Global Helps Clients Turn Ideas into Impact

The collaboration with Parexus reflects what Lizard Global does best: helping ambitious companies translate complex ideas into scalable, user-centered digital products. From software development to UI/UX design, Lizard Global supports clients across the full product journey, from defining workflows and integrating advanced technologies like AI, to building platforms that teams actually want to use.

Whether you are a deep-tech startup looking to operationalize AI, or an established enterprise navigating Industry 4.0 transformation, Lizard Global brings the strategic thinking, technical expertise, and human-centered design needed to move from concept to impact.

Because great technology only delivers value when it fits seamlessly into the way people work - reach out today start the conversation.

Manual inspections, scattered workflows, and slow reporting have long defined on-site engineering. Parexus is changing that narrative with AI-powered inspections and a smart digital platform built for real-world conditions. This client story explores how Sentry brings structure, speed, and clarity to Industry 4.0 operations.

Engineering sites are not short on data. What they lack is time. Time spent walking large facilities, manually inspecting assets, documenting issues, escalating findings, and waiting for approvals. For decades, this has been the reality of on-site engineering work, critical, complex, and heavily manual. Parexus set out to change that.

As a deep-tech startup operating at the intersection of AI and engineering, Parexus isn’t chasing innovation for innovation’s sake. They are solving a very real, very human problem: how to reduce manual inspection work on engineering sites while increasing accuracy, accountability, and speed.

This is where their Sentry platform, and their collaboration with Lizard Global, began.

Want to find out how much it costs to build your dream app or web app?

Meet Parexus: A Deep-Tech Startup with a Clear Mission

Parexus is a deep-tech startup focused on integrating AI into the engineering industry. Led by Jeremy Ong, the team recognized a critical gap in how inspections and maintenance processes are handled on-site.

In industries operating under Industry 4.0 standards, engineering inspections are still largely manual. Engineers on-site are required to visually inspect assets, capture findings, write reports, and escalate issues through multiple layers of review. The process is time-consuming, prone to inconsistency, and heavily dependent on individual experience.

Parexus envisioned a smarter way. Their idea was simple in concept, yet complex in execution: empower engineers on-site to take photos, submit them through a digital platform, and let AI analyze the images to determine whether maintenance is required. The result would be faster inspections, standardized reporting, and clearer decision-making.

What they needed was not just AI, but a platform capable of supporting the entire workflow around it.

The Real-World Challenge: Manual Inspections at Scale

On-site engineering inspections involve far more than just checking assets. There are campaigns to organize, teams to assign, inspection routes to plan, and multiple stakeholders to keep aligned.

Admin teams must define maintenance campaigns, operators must carry out inspections, and quality teams must validate results before work is approved or escalated.

Before Sentry, this process was fragmented. Engineers relied on manual documentation, disconnected tools, and repeated back-and-forth between roles. Inspections could take longer than necessary, and insights were often delayed by process bottlenecks rather than technical limitations.

Parexus needed a way to orchestrate this complexity, without slowing teams down.

The Sentry Solution: AI-Powered Inspections Backed by a Smart Platform

Sentry was designed as a responsive web application and Progressive Web App (PWA) that acts as the backbone of Parexus’ AI-powered inspection workflow.

At its core, the solution integrates Parexus’ proprietary image analysis AI into a structured, role-based platform that supports the entire maintenance lifecycle.

The process begins with the admin. Admins are responsible for setting up inspection campaigns. They define what needs to be inspected, assign team members, and map out routes for operators to follow on-site. Inspired by operational models used by industry leaders like Petronas, the system helps optimize inspection paths so engineers can move efficiently across large sites.

Once a campaign is live, operators, typically engineers on-site, receive their assigned inspections through the app. They follow the predefined route, capture images, and submit them directly within the platform. This is where Artificial Intelligence (AI) steps in. Between the operator and the quality control stage, Parexus’ image analysis AI evaluates the submitted photos. If no issues are detected, the process can move forward without delay. If potential problems are identified, the findings are flagged for further review.

A Structured Workflow Built for Engineering Reality

One of the defining strengths of the Sentry platform is how clearly it reflects real-world engineering workflows. The system supports four key roles, each with a distinct responsibility.

Admins handle campaign setup, route planning, and team assignments. Operators perform on-site inspections based on their assigned campaigns. The AI acts as an intelligent layer between inspection and validation, analyzing images and surfacing actionable insights. Quality Control (QC) managers review findings and approve next steps, while Quality Assurance (QA) managers handle escalations when issues require deeper investigation or rework.

If problems arise, the workflow allows findings to be escalated from QC to QA, and, if necessary, back to the operator for reassessment. This creates a closed feedback loop that ensures issues are addressed, verified, and documented, without losing visibility along the way.

The result is a system that mirrors how engineering teams actually work, rather than forcing them to adapt to rigid software constraints.

Lizard Global’s Role: Turning AI Vision into a Scalable Platform

While Parexus brought deep domain expertise and proprietary AI technology to the table, they needed a digital partner to bring the platform itself to life.

Lizard Global supported Parexus across software development and UI/UX design, ensuring the platform was not only technically powerful, but also intuitive for engineers working in demanding on-site environments.

From a user experience perspective, the challenge was clear: the app had to be fast, responsive, and easy to use, even in less-than-ideal conditions. Operators needed to submit inspections quickly, admins needed clarity over campaign status, and quality teams needed confidence in the data they were reviewing. From a technical standpoint, the platform required seamless API integration with Parexus’ AI, a reliable feedback loop between roles, and the scalability to support growing inspection volumes across sites.

Together, these elements formed a cohesive system designed for real-world use, not just theoretical efficiency.

Key Features That Drive Impact

The Sentry platform brings together several critical features that support AI-powered inspections at scale. Engineers can submit inspection images directly through the app, reducing reliance on manual reporting. A built-in feedback loop ensures findings are reviewed, escalated, and resolved within a single system.

API integrationsallow the AI engine to analyze images in real time and return detailed reports. Campaign management tools give admins visibility and control over inspections, routes, and team assignments.

Because the solution is delivered as a responsive web app and PWA, teams can access it across devices without compromising performance or usability.

The Impact: Less Manual Work, Smarter Decisions

The impact of Sentry is felt where it matters most, on-site. By automating image analysis and streamlining inspection workflows, Parexus helps engineering teams significantly reduce manual effort. Inspections become faster, reporting becomes more consistent, and decision-making is supported by AI-driven insights rather than fragmented documentation.

Quality teams benefit from clearer visibility and structured escalation paths. Admins gain better oversight of campaigns and resources. Operators spend less time on paperwork and more time focusing on critical engineering work.

In short, automation doesn’t replace engineers, it empowers them.

Supporting Industry 4.0 Through Practical Innovation

Parexus’ work sits firmly within the principles of Industry 4.0: digitalization, automation, and intelligent systems that improve operational efficiency.

What makes their approach stand out is its practicality. Instead of forcing radical change, Sentry enhances existing processes with AI and thoughtful platform design. It respects the realities of engineering environments while introducing smarter, more scalable ways of working.

This balance between innovation and usability is what turns technology into real business impact.

How Lizard Global Helps Clients Turn Ideas into Impact

The collaboration with Parexus reflects what Lizard Global does best: helping ambitious companies translate complex ideas into scalable, user-centered digital products. From software development to UI/UX design, Lizard Global supports clients across the full product journey, from defining workflows and integrating advanced technologies like AI, to building platforms that teams actually want to use.

Whether you are a deep-tech startup looking to operationalize AI, or an established enterprise navigating Industry 4.0 transformation, Lizard Global brings the strategic thinking, technical expertise, and human-centered design needed to move from concept to impact.

Because great technology only delivers value when it fits seamlessly into the way people work - reach out today start the conversation.

FAQs

How is AI being used in on-site engineering inspections?

Why are manual inspection processes a problem in engineering projects?

What does an AI-powered inspection workflow look like in practice?

Who typically benefits from AI-driven inspection platforms?

How do digital platforms support Industry 4.0 in engineering?

What should companies look for when building AI-enabled engineering software?

How can software partners help turn AI ideas into real-world solutions?

similar reads